As part of our process of continuous improvement Alpha Rail has launched some changes to metal gate hinges that help simplifying the design and manufacture of gates. The end result is a gate that is essentially a ‘blank’ panel so that the appropriate hinges, latches or other fixings can be bolted on after finishing. The technical drawings below explain the options we have developed which enable the design of the gate to be unhindered by the need to build in hinges and fixings. Using the new hinge designs options mean we can mount pretty much anything just so long as the required distance has been allowed between gate end panel and the mounting post.

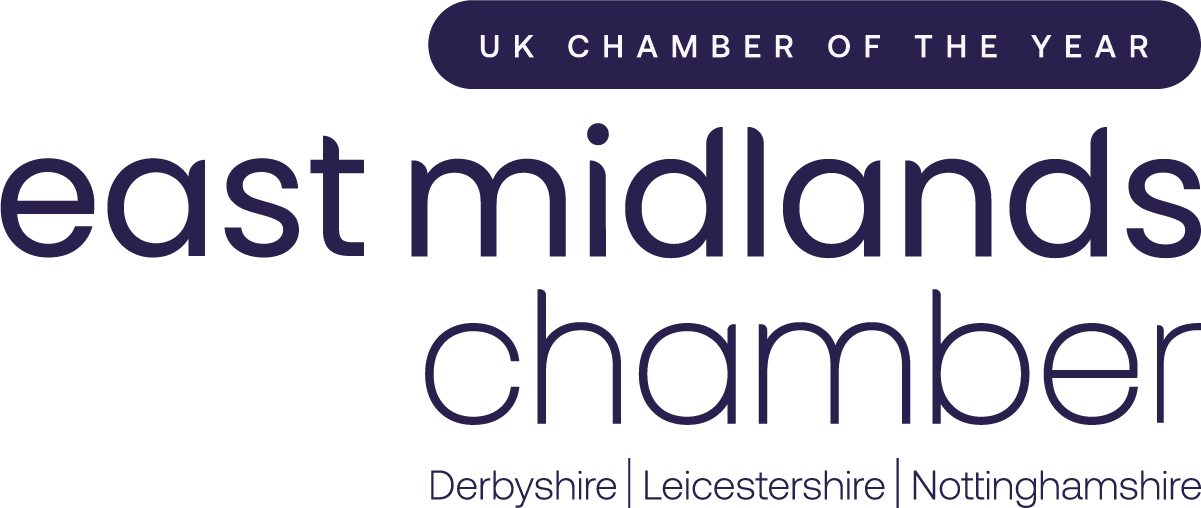

The majority of gates will be fitted using the M20 adjustable hinge, as per drawing ‘HINGE/RSF/002’ featured below.

Please note the following;

-

A standard 50mm distance from the far edge of the adjacent rail to the centre line of the hinge.

-

pH Bronze washers on all bottom hinges.

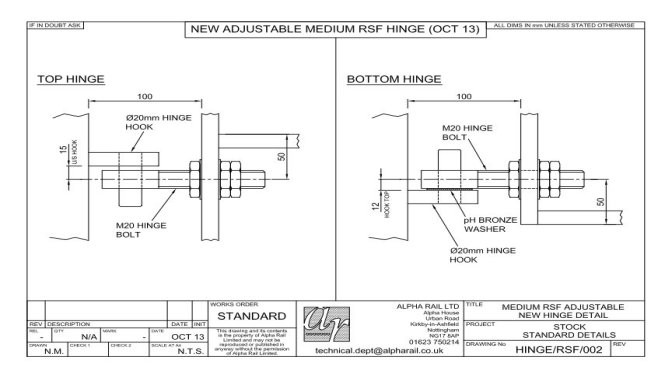

Where a gate has a larger section frame or where the weight is greater, then a slightly different version of the M20 adjustable hinge will be required as per drawing ‘HINGE/RHS/003 featured below.

Please note the following;

-

A standard 50mm distance from the near face of the adjacent rail to the centre line of the hinge.

-

pH Bronze washers on all bottom hinges.

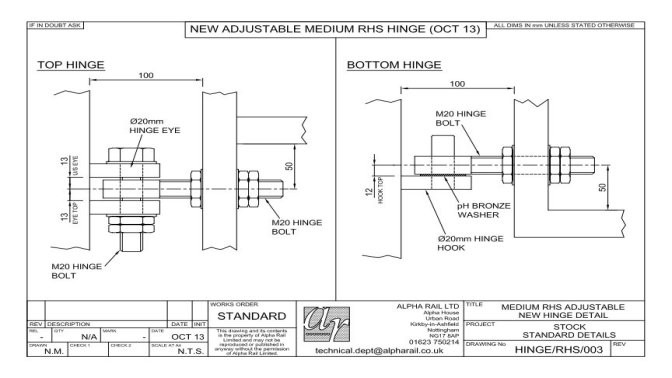

Please note the following;

-

A standard 50mm distance from the far edge of the adjacent rail to the centre line of the hinge.

-

pH Bronze washers on all bottom hinges.

-

M16 should be clearly marked on the main gate drawing.

———————————————————————————————————————————–

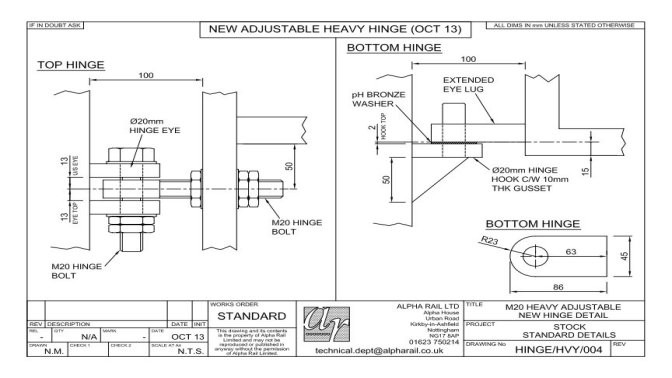

Where a very large or heavy gate is required then a special ‘Heavy’ version of the old adjustable hinge may be used, see drawing ‘HINGE/HVY/004’.

Please note the following;

-

A standard 50mm distance from the near face of the top rail to the centre line of the top hinge.

-

A standard 15mm distance from the underside of the gate to the centre line of the bottom hinge.

-

pH Bronze washers on all bottom hinges.

![AFI [MEMBER]](https://alpharail.co.uk/wp-content/uploads/2019/01/AFI-MEMBER-e1556273719380.png)